Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

Deco Technology Group has been producing precision silicone pad printing pads in Southern California since 1997. Our pads are designed for high-performance printing on plastic, glass, metal, and coated substrates—supporting industries including medical device manufacturing, automotive, promotional goods, and packaging.

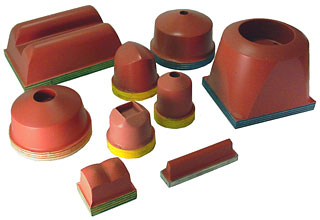

We offer hundreds of stock pad shapes, multiple silicone formulations, and a full range of durometer options to match your exact print needs. Whether you're decorating curved surfaces, recessed areas, or fine-detail graphics, our pads ensure optimal ink pickup and clean image transfer with long-term durability.

All pads are manufactured in the USA using premium-grade German silicone and can be custom-shaped to your part geometry.

We offer three proprietary silicone formulations engineered for specific industrial printing challenges:

To support a wide variety of pad printing applications, Deco Tech offers one of the most comprehensive selections of silicone pad shapes and hardness levels in the industry.

Deco Tech’s silicone pad printing pads are trusted by manufacturers across a broad range of industries where precision, repeatability, and durability are critical:

Deco Technology Group's DuraPro silicone pads, developed in 1997, set the benchmark for excellence in the pad printing industry. Manufactured from high-quality German silicone rubber, DuraPro™ pads deliver superior durability, unmatched print quality, and exceptional performance across a wide range of applications.

Engineered for continuous flexing, DuraPro™ pads ensure consistent and repeatable ink lay-down with every print. Renowned as the industry standard for pad printing, these premium pads are optimized for extreme durability, providing:

Compatible with two-component inks, single-component inks, and UV pad printing inks, DuraPro™ silicone pads are the ideal solution for high-performance pad printing applications. Available in a range of hardness levels, from 65 to 20 Shore A (00 scale), these pads cater to various printing needs with precision.

Choose DuraPro™ silicone pads for the ultimate combination of durability, flexibility, and print quality—trusted by professionals worldwide to deliver consistent results. Contact Deco Technology Group to learn more and discover why DuraPro™ is the #1 choice in pad printing silicone pads.

Static energy is the leading cause of poor-quality results in pad printing, often affecting print clarity and precision. Standard silicone pads can quickly accumulate static energy during production, attracting dust particles and debris that compromise print sharpness and edge definition. This static buildup can also cause “spider webbing”, where web-like ink trails appear around artwork edges, ruining the print's quality.

Even more critically, static-charged pads pose a risk to sensitive electronics, potentially causing static discharge that leads to circuit failures during printing. Deco Technology Group's Stat-X™ silicone pads solve these challenges with their innovative anti-static formulation. Developed using conductive silicone polymers and fillers, Stat-X™ pads are designed to prevent static buildup entirely.

Available in 65 to 40 Shore A (00 scale) durometer, Stat-X™ silicone pads are perfect for achieving consistent, professional-quality results across various substrates and applications.

Choose Stat-X™ anti-static silicone pads for the ultimate in pad printing performance, backed by Deco Technology Group’s expertise in high-quality printing solutions. Contact us today to learn more about how Stat-X™ silicone technology can revolutionize your printing process.

Deco Technology Group’s Printz™ silicone pads are revolutionizing the pad printing industry, delivering premium performance at an unmatched value. Recognized for their distinctive "purple rain" color, these pads are crafted with a proprietary silicone rubber formulation that rivals high-cost alternatives in both quality and durability.

Join the Revolution in Pad Printing Materials

Discover why Printz™ silicone pads are becoming the go-to solution for businesses seeking high-performance, cost-effective pad printing materials.

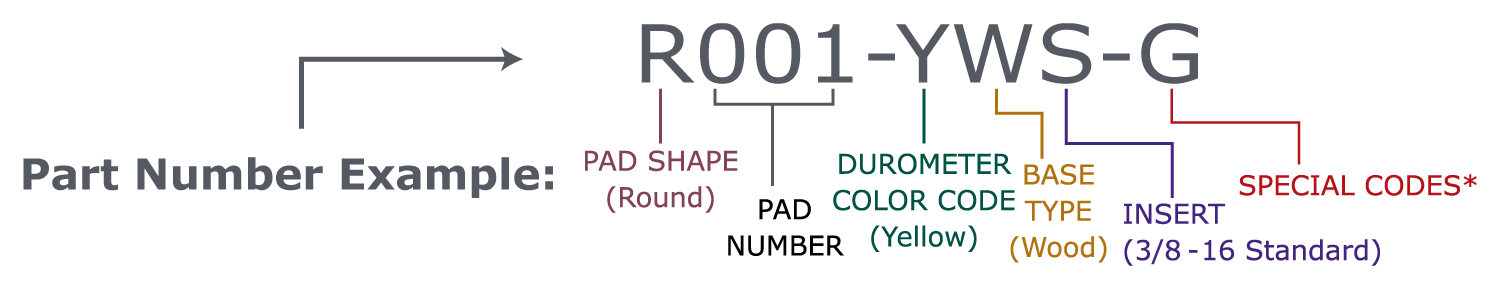

Each silicone pad we manufacture is identified by a unique part number that encodes the shape, durometer, base material, insert type, and any special attributes. The part number system helps ensure accurate reordering and simplifies communication when requesting samples or custom tooling.

The diagram below shows how to interpret a part number like R001-YWS-G, with details for each section including:

| 1) PAD SHAPE PREFIX CODE |

|---|

| An alpha character prefix defines shape of the pad |

| R = Round |

| S = Square |

| V = Vee or Stick |

| L = Loaf |

| C = Custom |

| 2) PAD NUMBER |

|---|

| We assign pad numbers consecutively as we create new molds. The pad number has no bearing on the size of the pads. |

| 3) DUROMETER COLOR CODE: | |||||

|---|---|---|---|---|---|

| All bases are color coded to designate durometer | |||||

| DuraPro™ | Stat-X™ | Printz™ | Color Code | Durometer (00) | |

| * | * | * | R=Red | 60-65 | |

| * | * | * | Y=Yellow | 50-55 | |

| * | * | * | G=Green | 40-45 | |

| * | B=Blue | 30-35 | |||

| * | O=Orange | 20-25 | |||

| 4) BASE TYPE CODE |

|---|

| All bases are available in five configurations. |

| A = .250” Aluminum |

| B = .500” Aluminum |

| C = .375” Aluminum |

| W = Standard Wood (12mm) |

| X = Thin Wood (5mm) |

| Y = Thick Wood (18mm) |

| 5) INSERT CODE: |

|---|

| Threaded Insert or Tapped in Aluminum |

| N = No Insert |

| M = Metric (6 x .1mm course) |

| S = Standard (3/8" - 16) |

| T = Tapped in Aluminum (10-32) |

| Q = Quarter / Twenty (1/4" 20) |

| 6) SPECIAL CODES: | |||||

|---|---|---|---|---|---|

| G = High Gloss surface | |||||

| P = Our PrintzTM formulation (purple silicone) | |||||

| X = Our Stat-XTM formulation (green silicone) | |||||

| Note: There is no special etension for our Dura Pro series (red silicone) | |||||

We’ll help you identify the ideal pad shape and durometer for optimal ink transfer and image quality. To get started, please have the following information ready:

Contact us at 714-639-DECO or email sales@decotechgroup.com for expert support.

One of the most frequently asked questions in the early stages of learning the do's and don'ts of the pad printing process is figuring out what pad to use for the part you are printing on.

Q: How do I choose the right durometer for my application?

A: Softer durometers (0–3 Shore A) are ideal for curved, textured, or irregular surfaces. Medium to hard pads (4–9 Shore A) offer better stability and are preferred for smooth, flat parts requiring high detail.

Q: Can I order custom pad shapes?

A: Yes. We offer in-house tooling and prototyping for custom pad shapes based on your part geometry. Simply provide part drawings or physical samples and we’ll design a custom-fit pad.

Q: How long do silicone pads typically last?

A: With proper care and cleaning, silicone pads can last for tens of thousands of print cycles. Durability depends on the pad formulation, durometer, and type of substrate being printed.

Q: Are your pads compatible with all pad printing inks?

A: Yes. Our silicone formulations are compatible with all industry-standard pad printing inks, including solvent-based, 2-component, and UV inks.

Q: What’s the lead time for custom pads?

A: Standard shapes are typically in stock and ready to ship. Custom pads usually ship within 5–10 business days depending on complexity and tooling requirements.

Q: Do you offer samples or test printing?

A: Yes. We can provide sample pads for evaluation and, upon request, run in-house print testing on your parts to recommend the ideal pad shape and durometer.